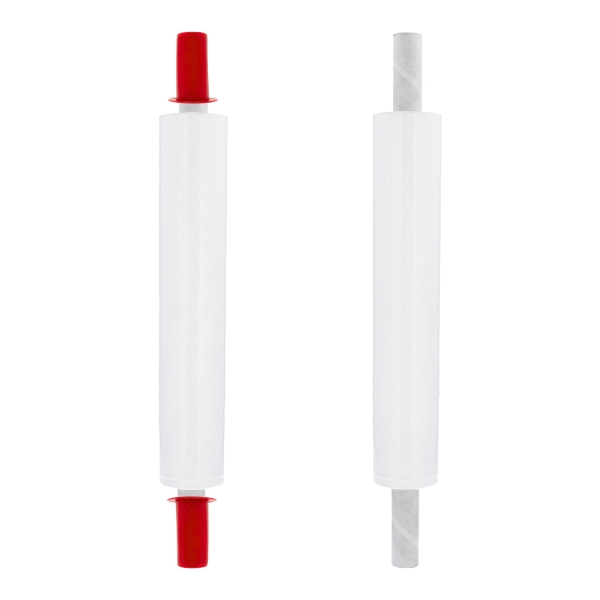

Selecting the right stretch wrap for your operation is critical to ensure optimal load stability and minimize damage during transportation or storage. Start by evaluating the weight, shape, and size of your pallets. For heavier or irregular loads, a high-performance or blown stretch film provides better puncture resistance and holding strength. Choose cast stretch wrap for quieter application and superior clarity when load visibility is a priority. Consider the application method: hand stretch wrap is suitable for smaller volume tasks, whereas machine stretch wrap improves efficiency in high-volume settings. Film gauge (thickness) also matters—thicker films offer more durability, while thinner films can reduce material costs without sacrificing performance for lighter loads. Lastly, factors in environmental conditions like extreme temperatures or outdoor storage, which might require specialized films with UV resistance or enhanced elasticity.

● Superior Load Stability: Keeps products tightly bound, reducing the risk of shifting during transit.

● Cost-Effective Protection: Offers an economical solution for safeguarding goods without a heavy investment.

● Enhanced Puncture Resistance: Durable enough to handle sharp edges and irregular load shapes.

● Improved Operational Efficiency: Machine-compatible options speed up packaging processes in industrial environments.

● Moisture and Dust Barrier: Shields products from contaminants, ensuring they arrive clean and intact.

Log In